Stock Keeping Unit (SKU)

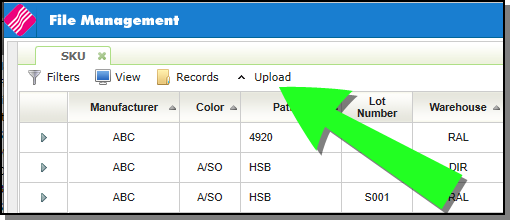

Stock Keeping Units (SKUs) are a combination of an item number, lot number, and warehouse code. Each item can have many different SKUs because items can be stocked in multiple warehouses and come in multiple lot numbers. An item might not have any SKUs. An item that had never been ordered or received would not have an SKU record on the system.

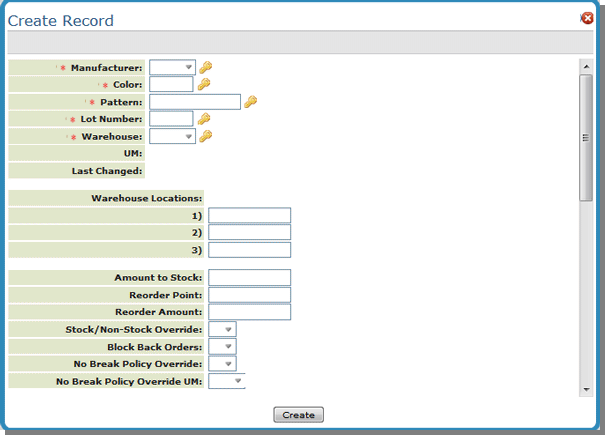

To create a new SKU File, click Records and then select Create.

| Field Name | Description/Instructions |

|

Manufacturer Color Pattern |

These components make up the item number. |

| Lot Number | Do not confuse lot number with serial number or shade, although you can use lot numbers for shades in some cases. If you use the serial number feature, the lot number is usually left blank. |

| Warehouse | The warehouse where the SKU is located. |

| Last Change | This field is not accessible. The date shown here is the date on which the last change was made to any of the input fields displayed on the SKU Profile screen for this record. |

| Warehouse Locations | |

| Location 1 |

The main (default) location in the warehouse for this SKU (eight characters). Leave these location fields blank if you use dynamic locating, in which items are located based on available space rather than reserved locations. For serial numbered items, limit the location to four characters because serial numbered items use a four-character location. The Laminate Cut Selection screen (accessed through CUS 1) checks and then uses these locations to help increase inventory accuracy by ensuring cut pieces are returned to the correct location. |

| Location 2 | Additional location in the warehouse for this SKU. Leave this field blank if using dynamic locations as described above. |

| Location 3 | Additional location in the warehouse for this SKU. Leave this field blank if using dynamic locations as described above. |

|

Override Fields These override fields enable you to establish which products are stocked in which warehouse, rather than just a global stock/non-stock flag. You may also have different no break policies in different warehouses. An item could allow broken cartons in one warehouse, and require full cartons in another warehouse. Order Entry and ISO will adhere to these warehouse level rules. |

|

| Amount To Stock | Optimum quantity to keep onhand of this item at this warehouse. This quantity overrides your entry in the related Product Line File record for this SKU. Leave this field blank unless you want to override the Product Line File entry. This quantity is always expressed in the native unit of measure for this item. |

| Reorder Point | Quantity below which a reorder should be generated. This quantity overrides your entry in the related Product Line File record for this SKU. Leave this field blank unless you want to override the Product Line File entry. |

| Reorder Amount | Quantity that should be reordered when the reorder point is reached. This quantity overrides your entry in the related Product Line File record for this SKU. Leave this field blank unless you want to override the Product Line File entry. |

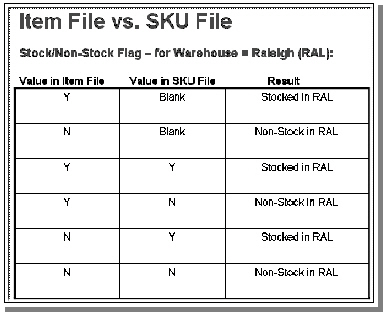

| Stock/Non-Stock Override |

Y (stock) or N (non-stock) in the Stock/Non-Stock Override Field overrides the Item File Inventory Flag for the purpose of reordering. Leave this field blank if the Item File inventory flag applies to all warehouses. Use this field only when one or more warehouses deviate from the overall status of the item. For example, if you stock an item in all but one warehouse, the Item File Inventory Flag should be set to Y, and the SKU File Flag set to N in the one warehouse. Other warehouse SKU entries should be left blank. This chart shows how programs will interpret the stock/non-stock flags.

|

| Block Back Orders |

If activated, this setting directs Order Entry (whether the order generation process be manual, ISO, or inbound CMS) to reject the creation of a back order for this item at this warehouse. Order Entry displays an appropriate message, and CMS rejects the order if stock is not available instead of back ordering. The default for this setting is N (blank = N). A Y in this field is the equivalent of the Item's Discontinue Date being before today, except that this flag can be for specific warehouses only, like discontinuing an item for specific warehouses. If this setting is activated, the system will not backorder the item. Instead the following message is displayed. Backorder cannot be placed for a discontinued item XXX XXXX X. If a stocking matrix exists for the item, the SKU file setting for the warehouse coded as the replenishment warehouse is used to determine whether a back order is allowed. The stocking matrix logic is used only when company settings to Force Back Order to Stocking Matrix are active. The normal business case for this feature is to manage the discontinuation of products in a multi-warehouse environment. For example, you may have branches that are out of stock in an item that is being discontinued and you prefer that they no longer sell the product except for what is left in inventory. However, there may be other warehouses that due to the proximity to the supplier or other factors, may still be allowed to back order the product. If you are in a multi-company environment, then it is possible the warehouse belongs to a company that may need to halt back orders prior to another company. |

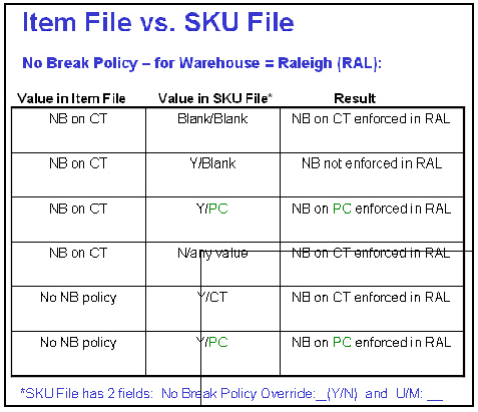

| No Break Policy Override |

Enter Y if the regular NB policy in the ITEM File should be overridden at this warehouse. If you enter Y, and you DO NOT enter a unit of measure in the next field, then the NB policy of the ITEM file will be ignored at this warehouse. If you enter Y, and you enter a unit of measure, then the NB policy uses this unit of measure instead of the Smallest Sales U/M in the item file, for this warehouse. It is recommended that you activate this field for dimensional products such as ceramic tile. The following chart shows how you should set the NB policy fields in the Item and SKU files in order to get the results you need in each warehouse.

|

| No Break Policy Override UM |

This field contains the U/M that is treated as the Smallest Sales U/M for this item, at this warehouse only - if the previous field = Y. If you enter Y in No Break Policy Override field, and you DO NOT enter a unit of measure here, then the NB policy of the ITEM file will be ignored at this warehouse. If you enter Y, and you enter a unit of measure, then the NB policy will use this unit of measure instead of the Smallest Sales U/M in the item file, for this warehouse. |

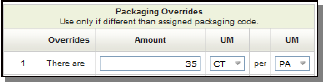

| Packaging Overrides |

Use these fields only if the packaging information for this particular SKU is different from the Packaging File for this item. These fields will temporarily add to or replace entries in the normal packaging fields when this SKU is processed. For example, an entry of...

...means there are 35 cartons in a pallet. |

| Month to Date Adjusted | You cannot update this field. It displays the quantity adjusted via cycle counts or adjustments in the current month. |

| Average Cost | You cannot update this field. It displays the current average unit cost for this SKU (this item/lot number at this warehouse only). If this is a serial numbered item, this is the average cost of all serial numbers in this warehouse or lot number for this item. |

| Accounting Cost | The value in this field overrides the accounting cost entered in the Cost File. Accounting cost should be used for recording LIFO costs, but can be used to store any alternative costs. These costs are controlled by the accounting department, and are never automatically updated by the system. These costs can be used by the Inventory Value reports. |

| Last Cycle Count Date | You cannot update this field. The date shown here is the date on which the last cycle count was processed for this SKU. This field is updated by the Cycle Count system, or when an adjustment is entered with code C for cycle count. |

| Operators Initials | The initials of the person adding or editing an SKU. |

| Inventory Status & Fiscal Year Statistics | |

| Beginning of Year Onhand | Amount available at the beginning of the year. |

| Average Cost | Average cost is the average unit cost of the onhand quantity for this SKU. A true weighted average is used. If this is a serial numbered item, then the average cost is for all serial numbers onhand in the warehouse and lot for this item. Do not confuse lot with serial number; multiple serial numbers can be in one lot number. |

| Received Year to Date | Amount received year to date. Yr-Dt always refers to the current fiscal year-to-date. |

| Last Cost | Last cost is the unit cost of the last receipt for the SKU. It is the last landed cost. |

| Base Cost | Base cost is the base (material) portion of the last cost. |

| Freight Cost | Freight cost is the freight portion of the last cost. |

| Manufactured Year to Date: | Amount manufactured year to date. Yr-Dt always refers to the current fiscal year-to-date. Manufactured Yr-Dt is entered only if your company manufactured this SKU and you have an interface to your manufacturing program. |

| Shipped Year to Date | Amount shipped year to date. Yr-Dt always refers to the current fiscal year-to-date. Shipped indicates invoiced. |

| Adjusted Year to Date | Amount adjusted year to date. Yr-Dt always refers to the current fiscal year-to-date. Adjusted Yr-Dt displays a positive number if it increased inventory, and a negative number if it decreased inventory. |

| Value Onhand | Value onhand indicates average cost multiplied by quantity onhand. |

| On Hand | The quantity physically existing onhand for this item in this warehouse. |

| Allocated | Allocated equals the quantity reserved on customer orders. Temporary holds are not included in this figure. |

| On Order | On order is the quantity scheduled (on purchase orders). |

| Available | Available equals the quantity onhand less the quantity allocated. |

| Last Cust Order Date | The date of the last customer order for this item at this warehouse. |

| Last Receipt Date | The date of the last receipt into inventory for this item at this warehouse. |

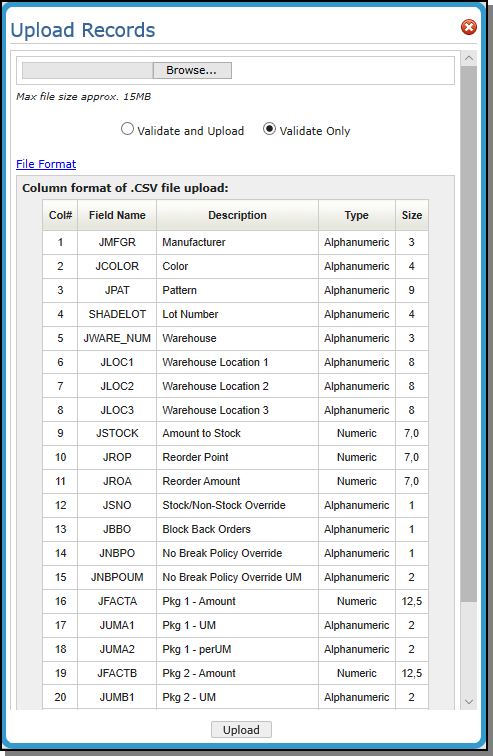

Upload Utility for SKU File

This functionality, added in March 2020 via Spec 6001, creates a method for adding and updating SKU file records from a spreadsheet.

Click Upload to display the Column Format that the spreadsheet needs to be in prior to uploading.

Prior to loading, you can choose to Validate and Upload the spreadsheet or just Validate it for errors.

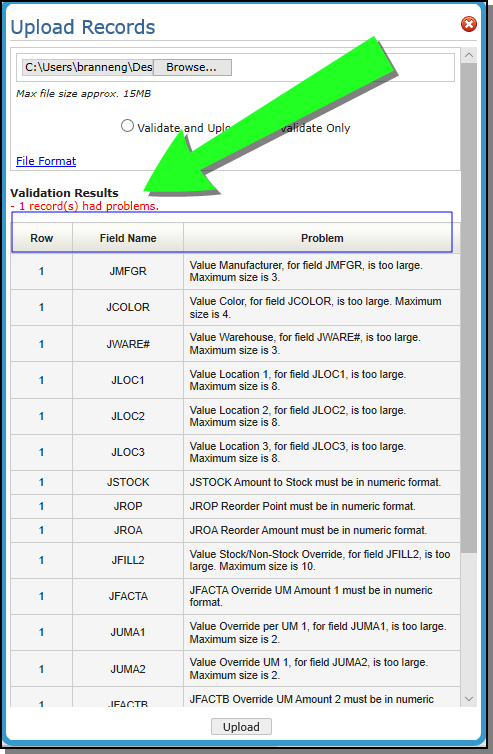

If there Validation issues, they are noted under the Validation Results heading.

If there are errors, the window displays:

- the Row where the error occurred

- the Field Name

- and the value that contains the Problem.

Downloading SKU Records

The SKU Upload spreadsheet template can also be used for ensuring downloaded SKU records are in the proper format.

- Download SKU records using the existing process.

- Make the necessary changes, updates or additions.

- Use the upload feature to bring that file in and have the changes or additions take effect.

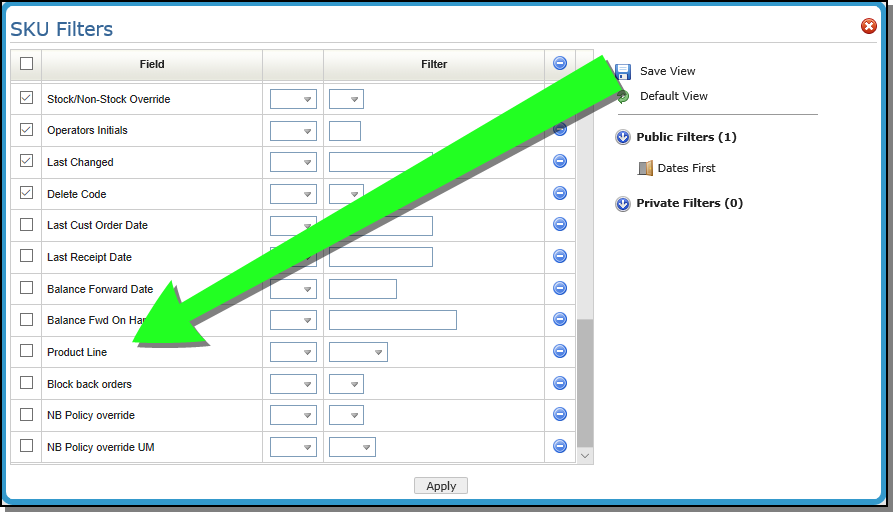

New Filter parameter

Since most records are added by product line, a filter has been added to allow you to only include records for items within a specified product line.